Always the look you’re looking for.

Gage Brothers precast concrete comes in almost an unlimited array of colors, forms and textures including exposed concrete, veneers of traditional materials, or a combination of both.

Colors

A variety of colors, aggregates, and finishes can be used to add drama and eye appeal to a single structure or choose a single look to create continuity and a signature appearance. For even more options, precast can also be painted or stained.

A combination of cement, aggregate, and pigment provide the precast color you are looking for. We utilize Dynamic Color Solutions pigments to provide integral color that will not fade or diminish over time. View our Project Gallery to see a variety of our precast concrete colors in use.

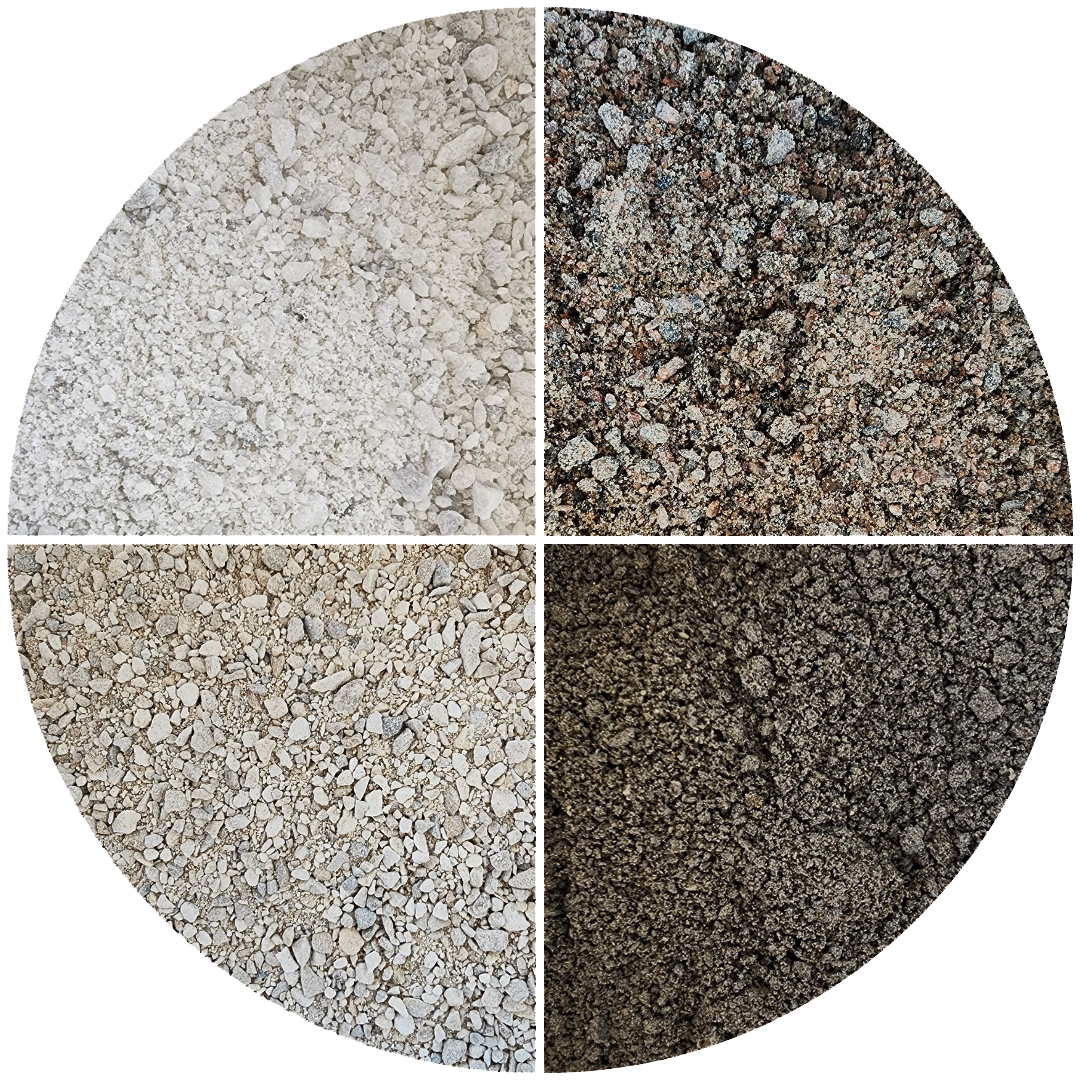

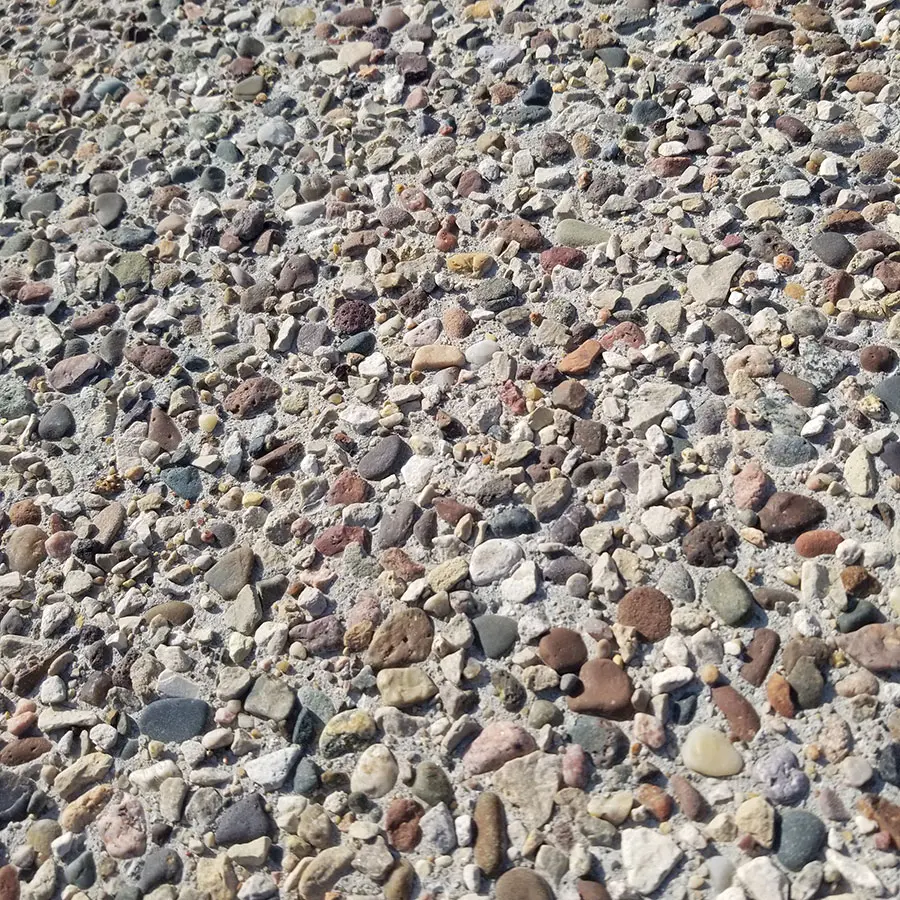

Aggregates

Utilizing different aggregates, such as granite, quartz, or limestone adds more depth and dimension to your building. Many colors and texture options are possible by varying aggregate type, color, finishing process, and depth of exposure.

Rock Aggregate

Sand Aggregate

Contact a Gage Brothers representative for more information about precast colors and finishes.

Call 605.336.1180 or send us an email

"*" indicates required fields

Finishes

Many traditional materials can be embedded in precast, including such as tiles, brick or terra cotta. Marble, granite and limestone can also be veneered / embedded into precast with the use of pins. Complete information about all of our finish options can be found by downloading our Color and Finish Guide Definitions.

SMOOTH

As Cast

Concrete is placed against hard, smooth formwork to achieve a smooth “as cast” finish on the precast element. Typically this finish is used in underground applications, elevator shafts, or structural products for example. This is the most economical finish since no further processing is performed.

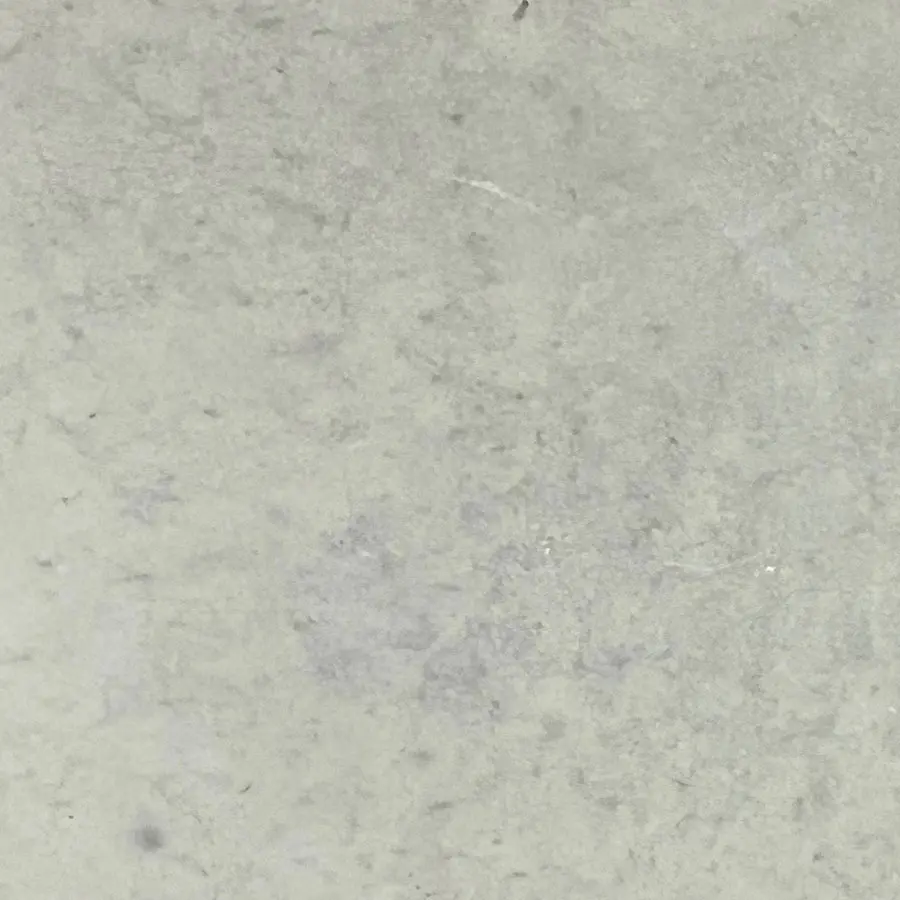

Light Sandblast

This finish is achieved by casting concrete against a smooth hard surface. After removal from the form, the element is given a light sandblasting. This light sandblasting will remove the cement skin from the surface. The resultant finish is a smooth, sand‐textured surface.

Light Etch

This finish is achieved by casting concrete against a smooth hard surface. After removal from the form, the element is allowed to harden to a uniform hardness. The product is then washed with an acid solution and scrubbed to remove the cement surface to a sand surface level. The result is a smooth sand-textured surface.

EXPOSED AGGREGATE

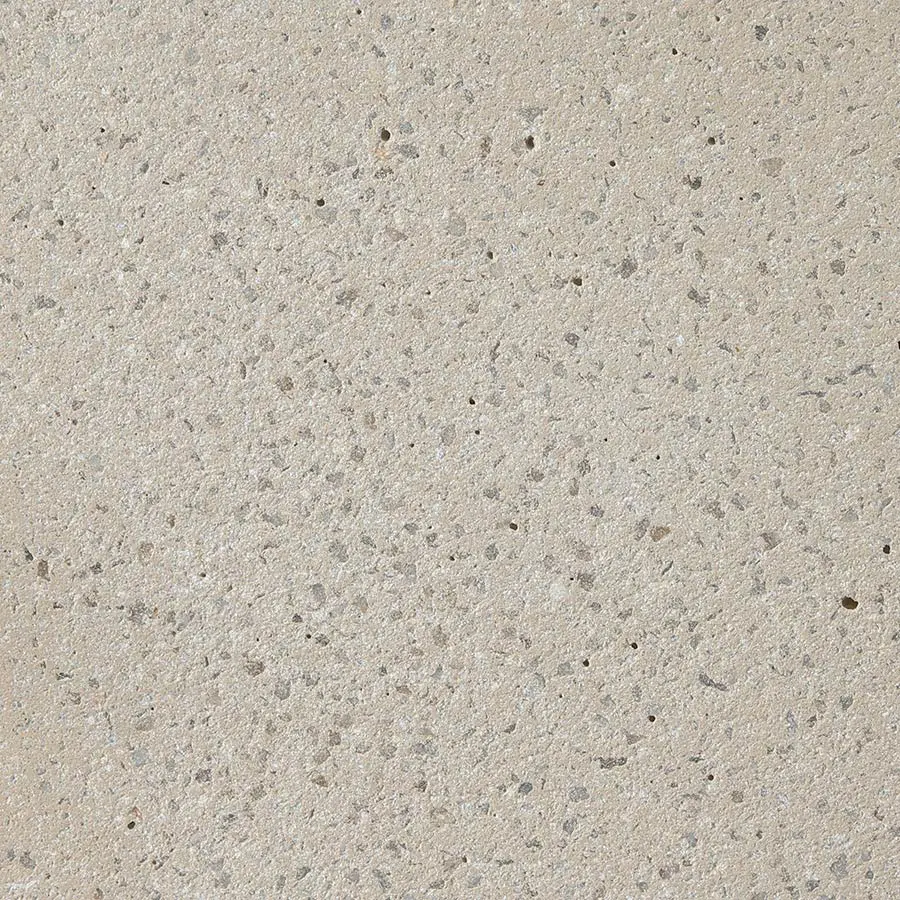

Chemically Retarded and Waterwashed

This finish is achieved by the application of a chemical retarder to the surface of the form. The retarder prevents the matrix from hardening at the surface of the panel to a specific depth, controlled by the strength of the retarder.

After curing (normally overnight), the unhardened layer of matrix at the surface of the panel is removed by a high‐pressure water washing, thus, exposing the aggregate used in the concrete.

OTHER FINISHES

Form Liners

This finish is achieved using plaster, “rubber,” grained wood, rope, or most other material as a liner in the casting form to impart a particular finish to the face of the panel. Textures could replicate stone, fractured, wood, rhythmic, flat, or masonry patterns. Form liners can be used multiple times during production.

Natural Stone Veneer

Natural stone cladding or veneer finish is achieved by placing natural stone (limestone, granite, marble) pieces into a form and casting concrete behind it to achieve a large precast panel having a natural stone face. Its purpose is to achieve a natural stone face on the building, while using the efficiency of precast concrete.

Brick Face Finish Panels

This is a precast panel with a cavity cast in, or a plate cast in if the brick runs to the bottom of the edge so that the brick can be set in the panel after its removal from the form. Thin brick or tile can also be set into a form and the concrete is cast behind it. In this case, the comments on natural stone panels would apply more closely.

Design Assistance

Gage Brothers’ experienced designers offer Design Assistance to help you explore the almost limitless possibilities of precast concrete design options and also ensure you remain within your budget.

| Design Documents |

|---|

| Color and Finish Guide Definitions |

| PCI Color and Texture Guide |

| Designer’s Notebook – Mixes Textures |

| Thin Brick |

| PCI Sample Process |

Sample Information

If you would like information on obtaining product samples, please fill out the form below and our team will be in touch to discuss.

"*" indicates required fields

605.336.1180

605.336.1180