A better way of building, inside and out.

Precast concrete can be used as integral structural support or architectural design elements for your next construction project. Engineers, construction managers and architects looking to maintain both quality and value choose precast concrete.

Precast Concrete Versatility

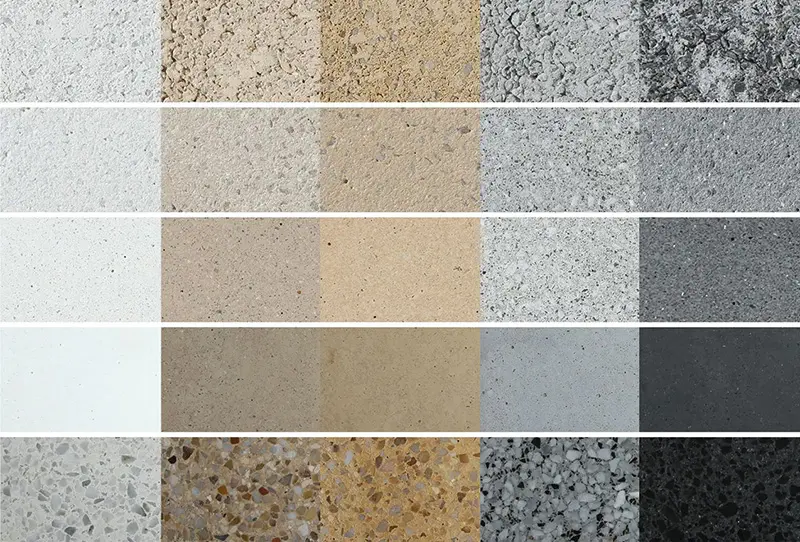

- Available in a multitude of colors, veneers and textures to fit visual aesthetic

- Designed to the project’s strength, thickness and length specifications

- Reusable molds used for consistency

- Production not affected by weather or jobsite conditions, enabling a 20-25% faster schedule

Precast Concrete Durability

- Transported ready for install to your jobsite after being prefabricated in our controlled facility

- Prestressing with steel rods or rebar increases strength

- Ultra High-Performance Concrete (UHPC) is unrivaled in strength, enabling broad span lengths and high load-bearing capability

Precast Concrete Sustainability

- Can be cast using recycled materials like steel rebar, fly ash or slag

- Able to last 100 plus years, and gets stronger with age

- Has potential to be crushed and used as aggregate in new concrete or as base road material

Precast Concrete in Minnesota & North Dakota

Gage Brothers is proud to have supplied precast concrete solutions for several construction projects in Minnesota, including Minneapolis, St. Paul, and the Twin Cities metro area. We’ve also helped amplify and construct structures in Bismarck and Fargo, ND. Robb would be happy to discuss plans for any of your construction projects throughout Minnesota and North Dakota!

Products: Architectural Insulated Panels / Hollowcore / Smooth Grey Solid Panels

Project Type: Retail

Location: Sioux Falls, SD

What can precast concrete be used for?

Architectural Precast Applications

Enhance the façade of your building with Gage Brothers’ Architectural Wall Panels

- Nearly infinite form, texture and color options allow for custom design

- The embedding of typical materials (marble, tile, brick) or addition of etching makes it one-of-a-kind

- Add insulation for thermally efficient building envelopes that exceed code obligations

Structural Precast Applications

Attain floor, lateral and roof load structural integrity while refining blast protection, seismic resilience, and fire resistance

- Precast wall panels used for load-bearing can handle roof, lateral and floor loads

- Sandwich wall panels permit insulation between the two concrete layers, increasing energy efficiency and specified R-values

- Double Tees and Hollow Core Slabs are used for prestressed roof and floor systems with lighter weight and greater clear spans

- Precast columns and beams for quick, orderly installation

- Precast stairs, columns and stadia for rapid builds of theater, arena and stadium seating structures

- ER-POST™ truss systems allow for open floor plans and unique space layouts

- Precast, prestressed bridge girders for reliable structural integrity

Robb is very familiar with the Minnesota and North Dakota regions and knows how precast concrete solutions ensure your building project on both on budget and on schedule. Give Robb a call to get answers to all your questions.

651-206-1603Email RobbGet to know Robb

Robb Walrath Jr.Business Development Manager - MN / ND

Gage Brothers is a PCI® Certified precast concrete manufacturer

Gage Brothers is a PCI Certified precast concrete manufacturer and holds certifications in all three major groups – Architectural, Bridge and Commercial Structural Products.

We are entirely focused on the success of your project and take pride in being a true partner with our clients, adhering to your specifications and budgets.

Architectural Products

AA certified: AD, AC, AB and AT

Bridge Products

B4 certified

Commercial Structural Products

C4 certified

605.336.1180

605.336.1180