Smart Precast Moves: How Gage Brothers Helps Contractors Tackle Construction Risks Head-On

The construction industry continues to face mounting challenges—from labor shortages and supply chain disruptions to tighter profit margins and increasing project complexity. For many contractors, these risks aren’t just hypothetical—they’re real-world obstacles impacting schedules, budgets, and quality.

At Gage Brothers, we believe in meeting those risks head-on with smarter, more collaborative solutions rooted in the precision and predictability of precast concrete. Here’s how we’re helping project teams across the Midwest and beyond reduce risk and build with confidence.

1. Quality Starts With Collaboration

According to recent industry reports, 98% of contractors have experienced construction quality issues in the last three years. These issues—errors, rework, and misaligned expectations—aren’t just costly, they’re avoidable.

Our solution? Collaboration.

We work closely with project owners, general contractors, and design teams from day one to ensure our precast components are fully aligned with project goals, timelines, and site conditions. By integrating early, we minimize miscommunication and maximize coordination, preventing issues before they begin.

Our approach includes:

- Early design-assist involvement

- Customized samples and mock-ups to verify aesthetic and performance

- Transparent communication throughout design, fabrication, and erection

2. Leveraging Technology to Improve Build Outcomes

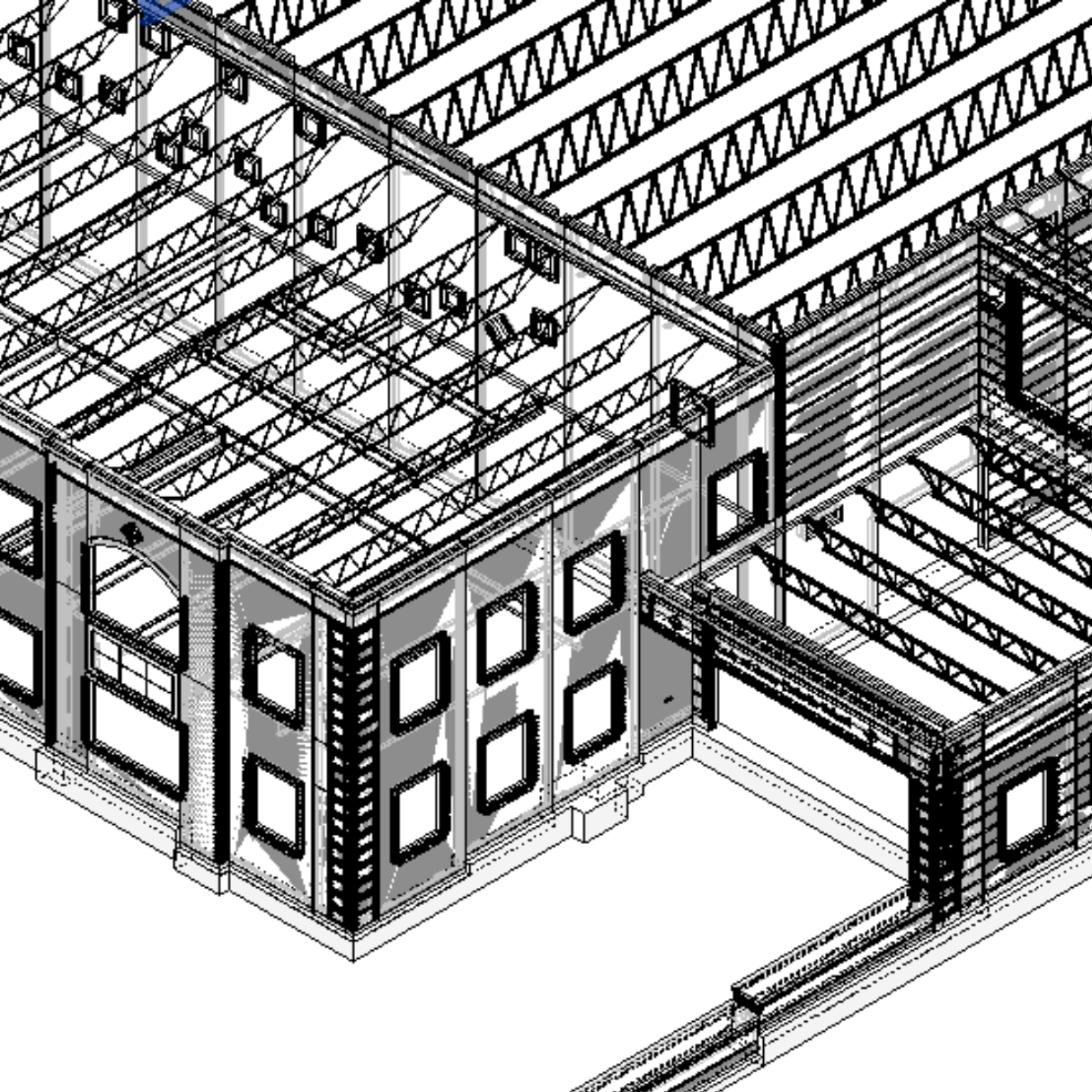

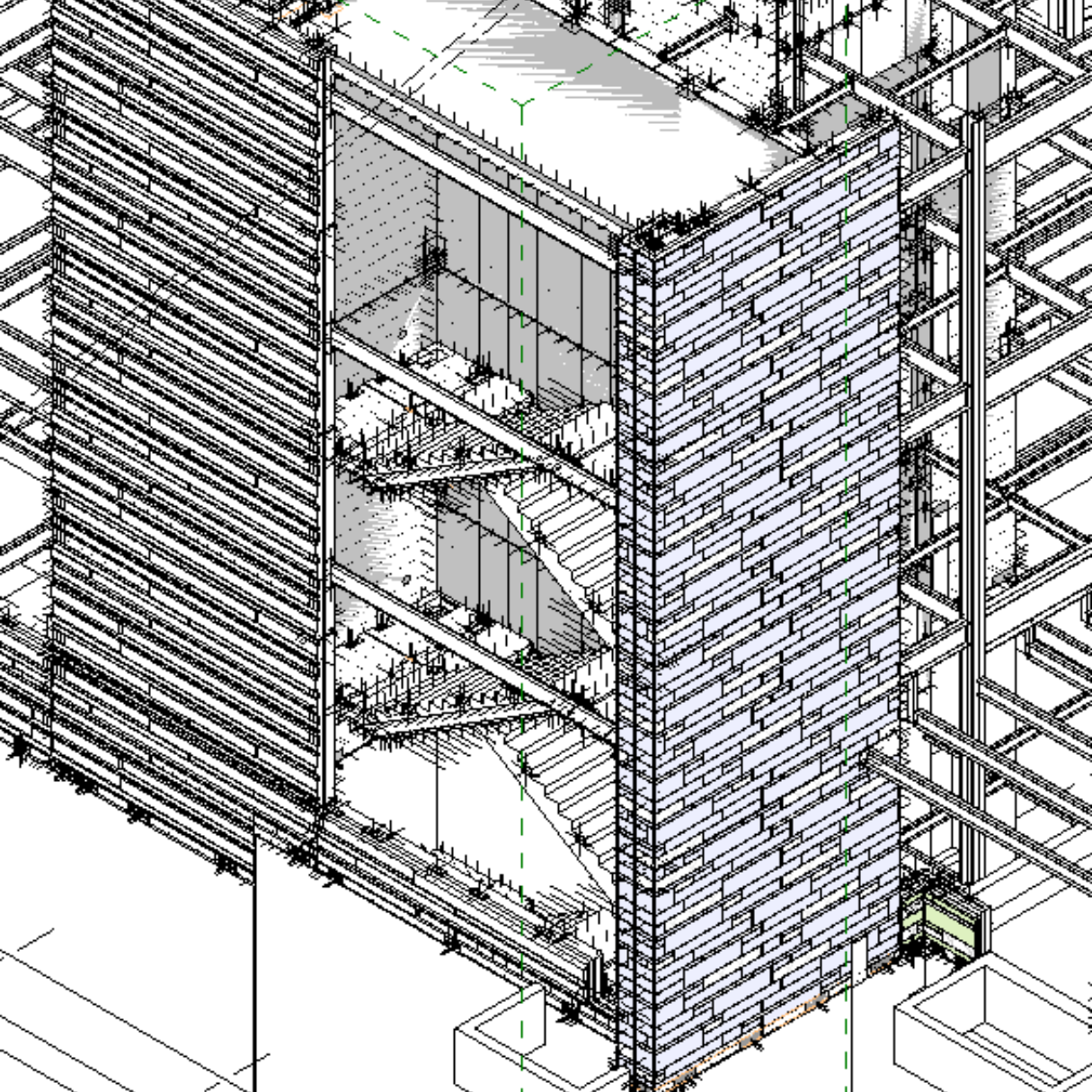

Many firms are still underutilizing tools like Building Information Modeling (BIM) in the field, resulting in errors and inefficiencies. At Gage Brothers, we use BIM not just for visualization, but for constructability and coordination.

How we make BIM work for you:

- Precast-specific BIM modeling for layout, connection detailing, and tolerance management

- Seamless collaboration with your design and construction teams to resolve conflicts digitally before they become field problems

- Model-to-mold workflows that reduce errors and deliver faster, more predictable results

The result? Greater accuracy, smoother installations, and fewer surprises on site.

3. Reducing Risk Through Schedule Certainty

Supply chain volatility and labor shortages are here to stay, but your project doesn’t have to suffer for it.

Gage Brothers helps control what can be controlled:

- Offsite fabrication that minimizes weather and labor risks

- Precise production schedules and just-in-time delivery to align with critical path timelines

- Reduced site congestion and fewer trades overlapping

Our precast systems—ranging from insulated wall panels to double tees and hollowcore—are manufactured under strict QA/QC protocols and arrive ready to install.

4. Field-Ready Support for Complex Coordination

Field crews today are managing more than ever before. 61% of field personnel say trade contractors often take on the bulk of cross-trade coordination, but many lack the tools to do it effectively.

Gage Brothers supports those frontline teams by providing:

- Clear shop tickets and erection drawings

- Dedicated field support and coordination meetings

- When applicable, smart layout integration using total stations and BIM data for enhanced accuracy

We don’t just fabricate precast—we help you install it faster and smarter.

Building With Confidence

In an era when risk is higher than ever, Gage Brothers is more than a manufacturer—we’re a proactive construction partner. From early engagement to final placement, we help you reduce risk, boost performance, and build it right the first time.

Let’s bring smarter solutions to your next project.

Contact our Gage Brothers precast team today to explore how precast can deliver safety, speed, and certainty.

605.336.1180

605.336.1180