A Game Changing Precast Concrete option featuring extreme Strength and Longevity

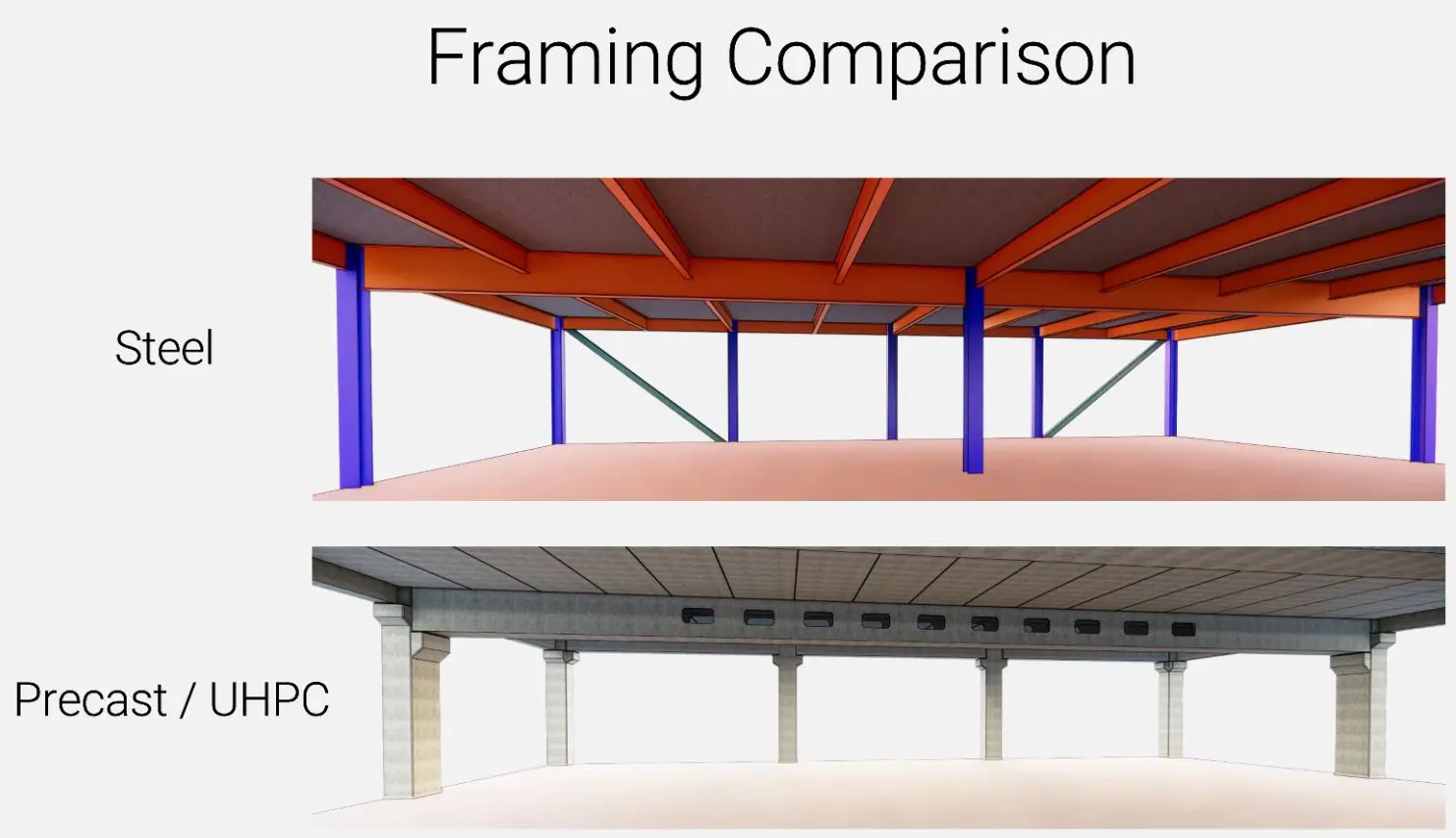

Ultra High-Performance Concrete (UHPC) is an advanced, high-strength concrete incorporating small, high-strength steel or synthetic fibers. This innovative blend not only eliminates the need for traditional rebar but also extends span lengths and reduces reinforcement requirements. Our precast concrete panels showcase unmatched strength and durability, making them ideal for architectural applications such as cladding and facade panels.

Gage Brothers specializes in delivering sustainable concrete solutions that meet the highest industry standards. Our UHPC panels are engineered with precision, offering exceptional performance in terms of load-bearing capacity and resilience. With a potential life expectancy exceeding 100 years, UHPC represents the forefront of modern construction materials.

Explore our range of UHPC products designed for architects and builders seeking cutting-edge concrete design solutions. Whether you’re looking for lightweight concrete panels, durable architectural concrete, or innovative concrete technology, our products promise to elevate your projects with unmatched quality and aesthetic appeal.

Plan your Project with Gage Brothers, and learn more about how UHPC can transform your next architectural endeavor.

Benefits of Ultra High-Performance Concrete:

- Enlarged clear span capabilities

- Reduced construction time with less material

- Better interior design flexibility

- Increased durability and building strength

- More sustainability with less ecological impact

Create a sustainable and timeless building that can reinvent itself to suit new tenants for centuries.

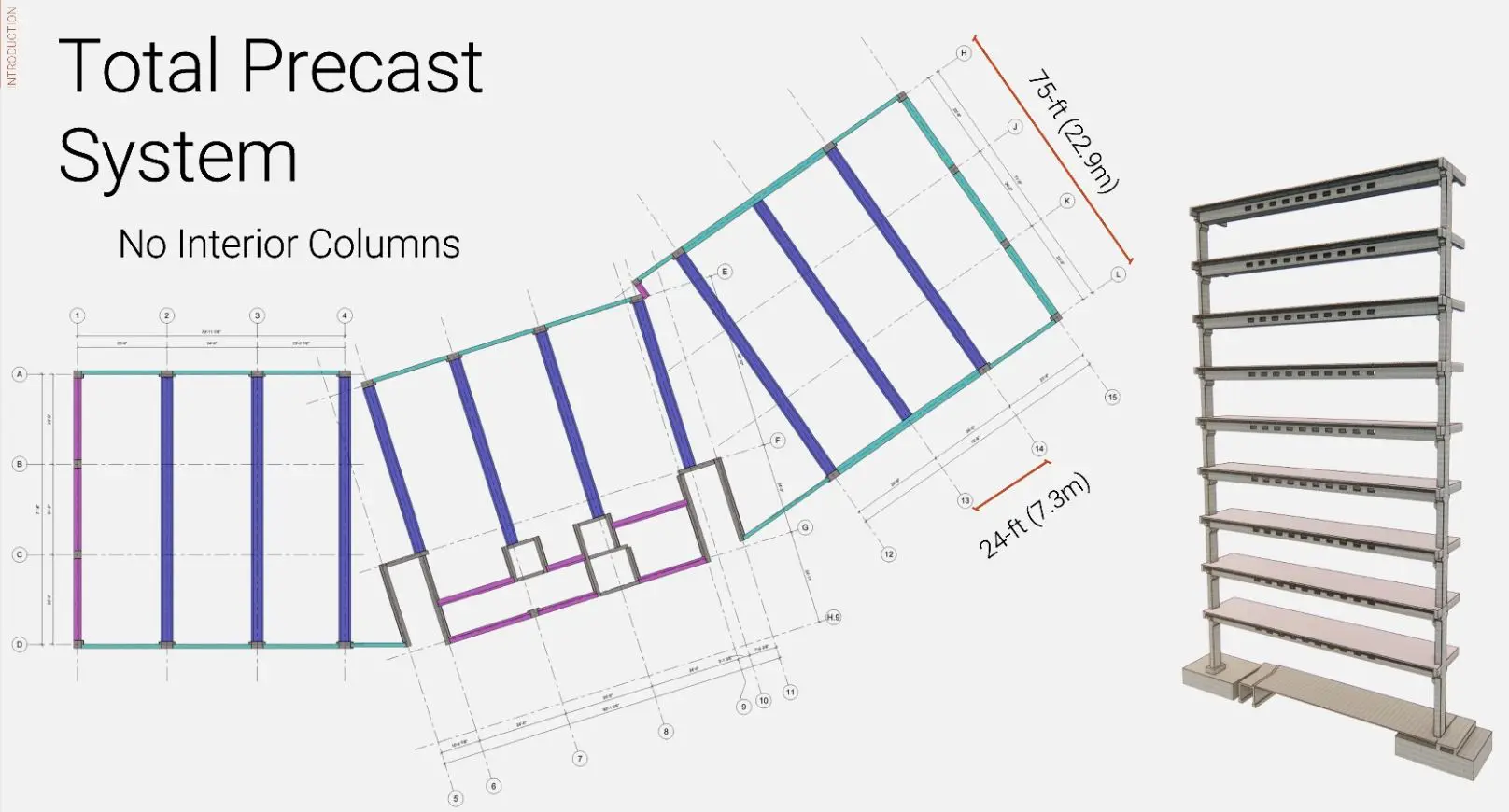

- Optimize your building’s complete framing system with UHPC to reduce the number of pieces and columns in interior spaces.

- Building owners will enjoy the flexibility of renting to a larger customer base with the increased space design options.

- Create open floor layouts that eliminate the need to design around beams that disrupt team collaboration.

- With fewer precast pieces, enjoy faster building erection timelines with fewer crane and workforce demands.

Talk with Joe Bunkers, President of Gage Brothers, about your next project.

Call 605.336.1180 or

Case Study: Trading Traditional Design for 70′ Clear-Span Spaces

The Steel District Office – Sioux Falls, SD

Situated on a historic riverfront campus, The Steel District Office project has emerged as a beacon of innovation and sustainability in the realm of mixed-use office buildings. A defining feature is its utilization of UHPC beams to eliminate interior columns, enabling unparalleled design customization and flexibility.

In conventional high-rise construction, 36-foot-long beams are supported by vertical columns. However, UHPC revolutionizes this process, enabling the creation of structures with double the span lengths with zero interior supports.

This total precast project encompasses 2908 precast concrete elements, including 86 UHPC beams that support the entire 175,000-square-foot structure. This innovative structural system, combined with expansive windows and open floor plans, ensures an unparalleled user experience characterized by abundant natural light, panoramic views, and adaptable spaces conducive to modern work environments.

“If you’re a tenant divided between a building that gives you complete layout flexibility and one that doesn’t — isn’t your choice intuitive? The value to the developer and the tenants speaks for itself.”

Keith Thompson, Principal Architect, Koch Hazard Architects

Awards:

- AWARD WINNER: Recognized by the Precast/Prestressed Concrete Institute, The Steel District Office wins the prestigious 2024 Harry H. Edwards Industry Advancement Award

- PCI Awards Publication – Spring 2024 Ascent

- AWARD WINNER: Third International Interactive Symposium on Ultra-High Performance Concrete (UHPC) “Best Innovation in Buildings” Award

In The News:

- First commercial use of UHPC debuts in office building – Ascent

- UHPC used in first-in-nation application in SD – PCI Journal

- How Sioux Falls’ Steel District leveraged UHPC for a completely custom design – MN Business Journal

- Steel District Office is a game changer for the construction landscape – Des Moines Register

- The future of office design is here – ENTER, AIA Minnesota

- Midwest collaborators build a case for ultra-high performance concrete – MSPBJ

- Unveiling the Power of UHPC Precast – IA Architect

- Game Changer – The commercial use of UHPC – Structure Magazine

UHPC Applications:

- High-Rise Office & Multi-Use Buildings

Redesign spaces for a variety of tenants. - Parking Ramps & Fire Separations

Remove hazards and increase parking spaces. - Larger Gymnasiums & Sports Arenas

Better sightlines and seating arrangements. - Conference Centers & Exhibition Halls

Open, flexible spaces for tradeshows and events. - Warehouse, Distribution Centers, Manufacturing Facilities, & Data Centers

Efficient operation layout and adaptable storage arrangements.

UHPC Is Put To The Test

Researchers at the University of Nebraska-Lincoln conducted an experimental investigation to evaluate the flexural and shear capacities of a new precast/prestressed ultra-high-performance concrete (UHPC) box beam with cast-in-place (CIP) concrete topping. Two separate tests were conducted on a beam with five 2 ft x 1 ft voids through the webs at the middle third for utilities.

Shear Strength Results

The UHPC box beam tested in shear had a measured maximum load that is 267% higher than the design-factored interface shear load.

The applied load corresponding to the interface shear factored demand is 89.4 kip. The maximum applied load in the shear test is 328 kip which is 267% higher than the demand.

Design Service Load

The measured cracking load is 137% higher than the design service load. The shear strength of the UHPC beam was 112% higher than that of the design factored load.

It was concluded that the UHPC test beam had a significantly higher flexure capacity than what was required.

UHPC is ideal for extreme environments, such as areas that experience very low temperature or wet areas and high stress locations like bridges, tunnels and towers. It also allows for the use of thinner panels and support structures while providing superior strength and reliability. UHPC is the next generation of concrete enabling engineers to use smaller sections for longer spans and greater load resistance with less reinforcement.

605.336.1180

605.336.1180