Mastering Precast Concrete with a Proven Sample Process: Your Blueprint to Consistency and Quality

In the world of precast concrete, success is often in the details. At Gage Brothers, we’ve seen firsthand how a well-defined sample process can be the difference between a project that meets expectations and one that exceeds them. But what exactly does our sample process entail, and why is it so crucial for the success of your project?

Let’s dive into the steps that ensure your vision comes to life with precision and quality.

Step 1: Design Stage with Pre-Bid Samples

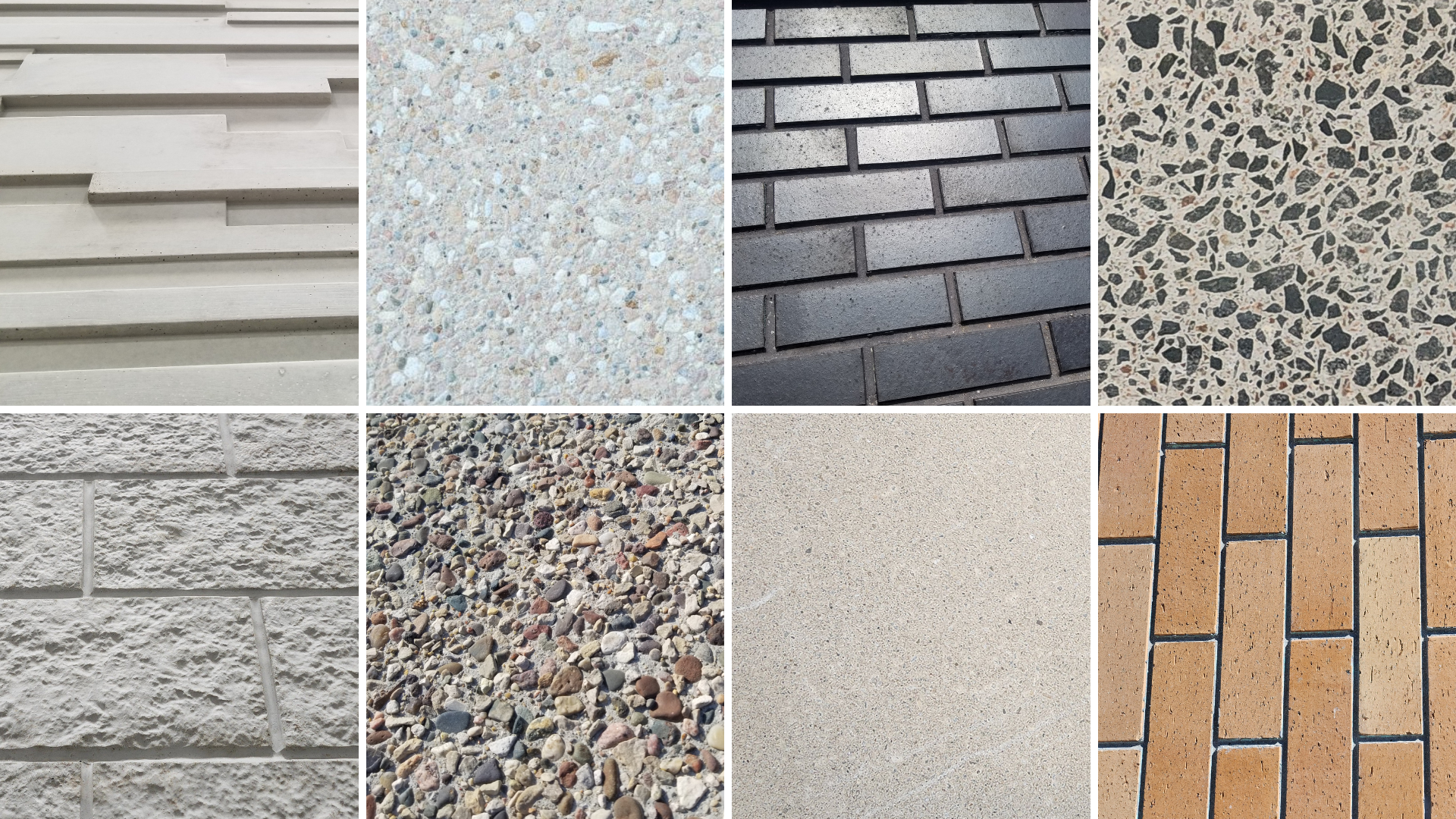

The journey begins before the first panel is even cast. Our pre-bid samples are the foundation of the entire process. These small yet mighty 12″ x 12″ x 2″ samples set the tone for your project’s aesthetic by establishing general color and texture examples. Think of them as the first brushstrokes on a blank canvas giving the designing architect their first vision of which precast finishes will work best on the project.

Pre-bid samples are hand-mixed in our production facility and can be shipped or delivered to design teams looking for concepts or examples to show project partners. Learn more about precast’s endless aesthetic possibilities with our Color and Finish Guide.

Step 2: Refining the Vision with Initial Samples

Once the project is awarded to Gage Brothers, it’s time to move to the 12″ x 12″ x 2″ initial samples. These samples play a crucial role in refining the overall vision of the building. At this stage, we’re not just talking about which color and texture anymore; we’re ensuring that every detail aligns with your design intent. It’s like fine-tuning an instrument to ensure perfect harmony.

Still hand-mixed, initial samples help Gage Brothers determine the exact color mix or depth of sandblast finish that is preferred.

Step 3: Bringing it All Together with the Standard Precast Mock-Up

Here’s where things start to get real. The production mock-up—typically larger at 4 ft x 4 ft x 6 in—serve as the gold standard for the entire project. Our mixing equipment creates production samples, giving a clearer understanding of what larger batches of the selected color and aggregate mix will look like.

These panels are no longer just samples; they’re a blueprint for consistency. Once approved, they become the production control sample, ensuring that every panel that leaves our facility meets the high standards we’ve set together.

Step 4: Defining Boundaries with Range Samples

Variations in color and texture are natural in precast concrete, but they need to be managed carefully. That’s where range samples come in. These panels help define the acceptable color range for your project. By collaborating closely with your team, we ensure that any natural variations fall within the agreed-upon spectrum, leaving no room for surprises.

Step 5: Full-Size Panel Mock-Ups

In certain projects where an added layer of assurance is needed, full-size mock-up panels can be requested by the owner and specified in the contract. These panels offer a full-scale representation of the precast elements, providing a real-world view of the final aesthetic and functional appearance before full production begins.

While full-size mock-ups are not always necessary, they can serve as a final approval tool for all stakeholders involved. By installing the mock-up on-site or in a controlled setting, teams can review the color, texture, and other details in the context of their environment. This is especially useful for large or unique projects where additional elements—such as windows, caulking, precast connections, and metal trim—are incorporated into the panel to give owners a comprehensive visual of the final product.

These mock-ups are not typical but provide valuable assurance when dealing with complex projects or unique architectural designs.

Why This Process Matters

You might wonder—why go through all these steps? The answer is simple: control and consistency. By following this process, we minimize the risk of costly delays, miscommunications, and rework. More importantly, we ensure that when the panels arrive on-site, they look exactly as you imagined.

At Gage Brothers, we believe in empowering our clients by providing them with the tools and processes needed to achieve excellence. By sticking to this tried-and-true method, we help you control the aesthetic destiny of your project.

A Few Tips for Architects Working with Precast Concrete

- Start Early: Engage with your precast partner early in the design assistance phase to ensure alignment on aesthetics and expectations.

- Stay Involved: Regular communication with our Preconstruction team members and Project Managers throughout the sample process is key. Don’t wait until the panels are on the job site to provide feedback.

- Trust the Process: Gage Brothers is a PCI Certified production facility. When we follow PCI’s recommended sample process, it isn’t just about checking boxes—it’s about ensuring your project’s success.

Ready to elevate your next project with Gage Brothers? Let’s start the conversation today and bring your design vision to life with the precision and quality you deserve.

Sample Information

"*" indicates required fields

605.336.1180

605.336.1180